Importing parameters is as easy as exporting them. Just follow these three easy steps, and JobControl® will be ready to start laser processing immediately.

Showing posts with label Trotec Software. Show all posts

Showing posts with label Trotec Software. Show all posts

Wednesday, October 19, 2016

Wednesday, October 12, 2016

Selecting the Correct Laser Focusing Mode

4 Focusing Options

To create a precise laser engraving, you must use the right lens, appropriate working tables and a corresponding exhaust system. Last but not least, using the correct focusing plays a key role. The correct setting of the focus - which means the right distance between the laser head and the material to be engraved - is crucial for a perfect application result. Trotec offers different modes for focusing.

Focusing with an Ultrasonic Sensor

The Sonar TechnologyTM works with

an ultrasonic sensor on the laser head. This sensor enables a very

precise distance measurement on every position of the working table. With only

one press of the button on the keyboard, the focus point is calculated

automatically based on the lenses selected in the software. The working

table will move in the appropriate focus position

automatically.

The Sonar TechnologyTM works with

an ultrasonic sensor on the laser head. This sensor enables a very

precise distance measurement on every position of the working table. With only

one press of the button on the keyboard, the focus point is calculated

automatically based on the lenses selected in the software. The working

table will move in the appropriate focus position

automatically.

This focus mode is suited especially

for all sound reflective materials. The Sonar TechnologyTM is a very

efficient focus mode. Patent is pending.

Light Bar Focus

The Light Bar Focus works with sensors

(light barriers) installed laterally in the enclosure. If the auto focus is

enabled on the keyboard of the laser system, the processing table will move up.

As soon as the material that you insert beforehand has passed the light

barriers, the upward movement of the table will stop. Focusing is then complete

and you can start the laser process.

The Light Bar Focus works with sensors

(light barriers) installed laterally in the enclosure. If the auto focus is

enabled on the keyboard of the laser system, the processing table will move up.

As soon as the material that you insert beforehand has passed the light

barriers, the upward movement of the table will stop. Focusing is then complete

and you can start the laser process.

The Light Bar Focus is ideal for flat

opaque materials where the material thickness is unknown.

Focus Using Bi-Directional Connection

The Software Focus is an elegant

method for approaching the exact height of the work table automatically. Thanks

to the bi-directional connection, the computer always knows exactly at what

height the work table is positioned. You then enter the material thickness and

the lens used. The Trotec JobControlSoftware automatically calculates the optimal focus point. The table

will then move to the correct position with only one press of the

button.

This focus mode is ideal for processing of materials of which the material thickness is known (ex. 6 mm Acrylic).

This focus mode is ideal for processing of materials of which the material thickness is known (ex. 6 mm Acrylic).

Focus Tool

The focus setting with the metal focus tool is fast and flexible. The operator simply hangs the focus tool on the laser head, and then moves the working table manually until the surface of the work-piece to be engraved touches the focus tool. Now the right focus point is set. The respective focus tool is pre-set to the focal length of the lenses and appropriately color coded.

This method is especially useful when

you work with a lot of different materials, if the material thickness is

unknown or cannot be measured and for cylindrical objects.

Wednesday, August 6, 2014

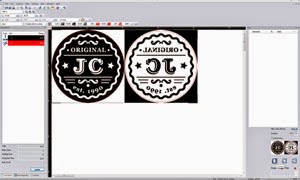

Simplified Seal Process in JobControl X

Every seal press consists of two die plates - the positive

(female) and the negative (male).

For the positive die plate (displayed as black text/graphics on a white background

in the graphics program) the black elements are engraved into the Delrin

material.

For the negative die plate on the other hand (displayed as

white text/graphics on a black background in the graphics program) the entire

black surface is ablated by the laser.

Consequently, the created text or graphic appears raised on

the die plate. The two die plates need to fit perfectly in each other to

achieve perfect relief print quality. That's why the text/graphic elements must

be produced slightly enlarged on the positive (female) plate. There is no need

to adapt the size of the female plate manually. JobControl X (from version 10.3

on-wards) automatically creates the positive (female) and the negative (male)

die plate with only one click by choosing the process type "Seal" in

the Trotec print driver.

Creating the Graphics

In this example, the graphics are created in CorelDRAW.

However, any other graphics program, such as Adobe Illustrator, Freehand, etc.,

may also be used. Please note that you don't have to draw the outer cutting

line and the positioning nose (triangle recess), JobControl X will do this for

you, allowing you to focus on the elements inside the cutting line - your

layout. JobControl X also automatically enlarges the elements according to the

selected paper thickness for the positive (female) die plate. In the

JobControl X software, we provide predefined seal templates according to

current seal sizes available on the market.

Send Graphics to the Trotec Laser Machine

- Send your graphic design to the laser by using the Trotec

print driver.

- Choose the size of your Seal

- Choose your material; make sure to activate engraving and

cutting process

- Select the process mode "Seal" and choose the

correct paper quality

- Start the laser engraving machine by clicking on the button JC

Produce Your Die Plates with the Trotec Laser Machine

- Your seal job now appears in your job queue; double click to

position the job on the plate at 0/0.

- Job preview is available of the negative (male) and positive

(female) die plate, notice that JobControl automatically created the positive

plate, the cut line, and the positioning nose.

- Now connect to your laser machine and start the laser process.

Machining and Assembly

After the laser processing, you just need to clean the die

plates, pate them into the seal press and then you can already emboss the

paper.

Simply wash the finished Delrin die plates with water and a

little soap or dish liquid and wipe off any still adhering dust with a brush

(clean using compressed air if necessary).

The die plates can be quickly pasted into the seal press

using the supplied doubled-sided adhesive circles. The recessed die plate is

pasted onto the top and the die plate with the raised text is pasted onto the

bottom (at the holes punched into the seal press itself).

- First fix the thicker of the two supplied double-sided

adhesive circles onto the back of the recessed die plate (female) → then paste

this die plate, with the "nose" pointing to the front, on-to the top

part of the seal press

- Now paste the thinner adhesive circle onto the back of the

die plate with the raised text (male) → pull off the carrier material on the

back → now fix the die plate with the raised text into the recess of the

already installed die plate, so that the two die plates snap together

- Tip: the two noses on the die plates should be perfectly aligned on top of each other → now press down on the seal press, whereby the second plate is fixed into the press → you can now place a piece of paper into the fully assembled seal press → press down → result: relief embossed paper

Thursday, January 30, 2014

New Version of JobControl X – Windows 8 Support

Windows 8 Support

The newest version of the most user-friendly and powerful

laser software on the market, JobControl 10.2, is now Windows 8 compatible.

With this release, Trotec is supporting the laser user in the best possible

way to be more profitable.

Enhanced Printer Driver Performance

All versions of JobControl optimizes your workflow with

top engraving quality and speed. With this update, printer driver bitmap

performance has been improved, this means your jobs are sent faster to the

laser machine.

With the Photo Optimization feature, you no longer need

additional software to enhance your bitmaps and photographs, JobControl

10.2 now does it in one click.

For more information on Trotec's JobControl and how this truly unique laser software can improve your production output, quality, and your return on investment, check out our website for more details on JobControl laser software.

Features for Optimized Engraving Quality

When JobControl was in introduced 12 years ago, the

Correction Value function was implemented to guarantee precise laser power

control for vector cutting. Now this feature has been expanded to support

engraving jobs. Guaranteeing Trotec users will always get the perfect cut, mark, and engrave... Even on the most precise and detailed jobs!

JobControl 10.2 is now shipping with all new

laser systems. Current Trotec Speedy users with JobControl 9 can

purchase an upgrade to JobControl 10 later this year.

Thursday, January 23, 2014

Speedy flexx Series: Maxximum Flexxibility

The Unique Laser System With Two Laser Sources is Now Available in the Compact Speedy 100 Model!

Speedy flexx Series

With a working area of 24 x 12 inches this unique dual laser source engraving, cutting, and marking system fits most standard material sizes. The machines of the Speedy flexx

series are equipped with both a CO2 and a fiber laser. This allows customers to

perform endless applications. The CO2 laser source is ideally suited for

engraving and cutting plastics, wood, rubber, leather, paper, amongst many other materials.

The fiber laser is the right tool for direct metal marking and staining plastics. The

machines of the Speedy flexx Series include the Speedy 100 flexx, Speedy 300 flexx and Speedy 400 flexx.

Maxximum flexxibility – For Both Applications and Businesses

Trotec's unique laser software, JobControl, guarantees time saving and

flexibility throughout the day.

Like all the lasers in our flexx series, the Speedy 100 grows with your business. All laser system are "ready for flexx", this means you can buy our laser with either a CO2 or a fiber laser source today and easily upgrade your system to a flexx when your business is ready to expand it's portfolio.

A strong family

With a large variety of options, such as various table and lens options, rotary engraving devices, and a camera vision system, Trotec and the Speedy lineup are ready to meet all your application and business needs now and into the future!

Wednesday, October 23, 2013

Material Parameter Imports for JobControl X

Trotec now offers material parameters of all Lasertainment applications for import into your JobControl X.

Trotec now offers material parameters of all Lasertainment applications for import into your JobControl X.

Try our Sapmple Applications

Easily integrate all laser settings by importing the material file into your database... Allowing you to quickly and easily complete Trotec's Free Applications!

Detailed Guide for Easy Import

Download you detailed step-by-step guide & import material parameters!

Download you detailed step-by-step guide & import material parameters!

Trotec laser machine with JobControl X (version 10.0 or higher).

Wednesday, May 8, 2013

Trotec Laser Remote App: The 1st iOS App to Control a Flatbed Laser

New Laser Remote App Allows You to Monitor Your Flatbed Laser with iPhone or iPad!

The first iOS App to control a laser is now available in the AppStore. Trotec's Laser Remote App facilitates the overview of current jobs. Thanks to the virtual working area and laser keypad, positioning your laser is only a tap away!

Reduce downtime and maintain an efficient workflow by connecting your Laser Remote App to one or several Speedy laser systems... With instant feedback and status messages you'll always know the status of your jobs.

With intuitive operating concepts, Trotec Laser is once again setting new standards for laser systems!

Key Features of the iOS App:

The Laser Remote App is now available for free in the AppleStore. It is compatible with iPhone, iPod touch, and iPad with iOS 6.0 or higher. Required: Wi-Fi, Laser Software Job Control X, and a compatible Trotec laser system.

The first iOS App to control a laser is now available in the AppStore. Trotec's Laser Remote App facilitates the overview of current jobs. Thanks to the virtual working area and laser keypad, positioning your laser is only a tap away!

Reduce downtime and maintain an efficient workflow by connecting your Laser Remote App to one or several Speedy laser systems... With instant feedback and status messages you'll always know the status of your jobs.

With intuitive operating concepts, Trotec Laser is once again setting new standards for laser systems!

Key Features of the iOS App:

- Remote Control of Connect Laser

Know when the laser system is running or waiting for new jobs! - Laser Operation

Pause current job and control your Trotec Atmos exhaust - Laser Positioning

Easily move the laser head using the virtual keypad. You can also guide the laser head by touching the virtual working area! - Calculation of Engraving and Cutting Time

Provides user the total and remaining processing time of current laser job! - Much Much More!

The Laser Remote App is now available for free in the AppleStore. It is compatible with iPhone, iPod touch, and iPad with iOS 6.0 or higher. Required: Wi-Fi, Laser Software Job Control X, and a compatible Trotec laser system.

Thursday, December 13, 2012

How to Print from Adobe Illustrator

Easy Workflow:

One of the most frequently asked

questions is “Do I need to print from CorelDraw® or can I work with my preferred

graphic program?”

JobControl is compatible with all graphic programs! Today, we are going to break down the workflow for Adobe

Illustrator®.

Getting Started: Three Things to Remember

- When creating a new document, please use a basic RGB document.

- When opening an existing document, make sure, that in File - Document Color Mode “RGB Color” is activated. This ensures that the colors are interpreted correctly.

- For cutting lines, define line color RGB 255/0/0 and line width of 0.001 mm or 0.003 pt.

Print

Setup: Done Within a Few Clicks

- Go to “File – Print”: The Print dialog box of Illustrator shows up. Additional information for users of Adobe Indesign: In the InDesign Print

dialog box select “Output” and activate Color “Composite RGB”. Like this, the

printer interprets colors correctly.

Click on "Setup": A Print Setup Dialog Box notification will pop up.

Click on "Setup": A Print Setup Dialog Box notification will pop up.

- Click on "Continue": This will launch the Print Setup Dialog Box.

- Select the Trotec Printer and Click on "Preferences": This will launch Trotec's printing preferences.

- Adjust the size, material, and process settings as necessary. Then Click on "OK" to save and close Trotec's printing preferences.

- Click on "Print": in the Print Setup Dialog Box of the operating system.

- Click on "Print": in the Print dialog box of Illustrator. The job is transferred to JobControl. Pull your artwork from the Job Queue to the Job Plate.

To check the cutting lines turn on

“WYSIWYG” (What You See Is What You Get”) and check the color of the cut line.

The color will be pure RGB red.

Thursday, October 18, 2012

Using Lasers for Pre-Printed Materials

Achieve Perfect Finishing of Printed Materials with i-cut and Trotec laser systems

The i-Cut vision system is avaiable on several Trotec models, visit our website to learn more about i-Cut and Trotec Laser systems... You can also watch this cool video of the i-cut vision system in action!

Printed

signs, displays or POS materials can be cut individually with laser

technology combined with i-cut. During the process, the cutting line

follows exactly the specifications of the printer. In other methods,

minor distortions in the impression can easily produce inadequate

results. i-cut, on the other hand, is an intelligent and easy-to-use

system that detects any distortions in the impression. No matter if

these are linear or non-linear distortions – the cutting path is adapted

automatically and dynamically. As a result, the cutting line will

always perfectly match the impression on flexible or rigid materials.

How does i-cut work?

Registration marks are printed along the graphic. The camera is mounted to the processing head of the laser and registers the dimensions of the print by "reading" the registration marks before the cutting process. By comparing the "read in" registration marks of the impression with the target position in the original cutting file, i-cut can detect and compensate any deviations. During this process, the software will not only correct rotations. It also adapts the cutting path if the impression is distorted or inclined. At the same time, the i-cut software is very easy to use. A perfectly cut end product is thus guaranteed.

i-cut offers a wide range of sophisticated functions

How does i-cut work?

Registration marks are printed along the graphic. The camera is mounted to the processing head of the laser and registers the dimensions of the print by "reading" the registration marks before the cutting process. By comparing the "read in" registration marks of the impression with the target position in the original cutting file, i-cut can detect and compensate any deviations. During this process, the software will not only correct rotations. It also adapts the cutting path if the impression is distorted or inclined. At the same time, the i-cut software is very easy to use. A perfectly cut end product is thus guaranteed.

i-cut offers a wide range of sophisticated functions

- i-cut is easy to use

- i-cut corrects linear or non-linear distortions as well as rotations

- Reliable registration mark detection

- Cutting path preparation

- Material database- Intelligent workflow

- Ultra-bright LED lamps mounted directly to the camera

- i-scriptTM workflow: ai-Cut™ and i-cutCDR™

Watch the i-Cut in Action!

The i-Cut vision system is avaiable on several Trotec models, visit our website to learn more about i-Cut and Trotec Laser systems... You can also watch this cool video of the i-cut vision system in action!

Thursday, August 30, 2012

Independent Product Review

In today's day and age an investment in new equipment can be uneasy. We understand that, which is why we offer many tools to ensure you that you're making the right decision for your business, application, and future.

We love our product and stand behind it 100%! But don't take just our word for it, listen to what others have to say too!

Product Review: Engravers Journal, September 2011, "Product Review: Trotec's Speedy 300" By: J. Stephen Spence.

Thursday, January 26, 2012

DirectMark

In 2011 Trotec presented DirectMark, the first print driver using a printing function from any software for direct part marking with a galvo laser system. And now our recent release features many new fun and exciting features!

Organizing Your Printing Jobs:

Optimizing the features of our first release, managing print jobs will now be easier than ever!

Job Time: In order to facilitate job time estimation and productivity the marking time is now displayed for each job!

Job History: Provides a comprehensive overview of how many copies were marked, a what time, and how long each mark too.

Archive: Now you can save spool files, so when additional copies are needed after completing production you can reload the directly instead of having to print them again from your graphic software.

Password Protection: Never lose your optimized settings again... With a password protection your unique settings are just a click away!

New Hardware Options:

Added features increase the productivity and versatility of your laser!

Rotary: The new DirectMark 1.2 release is compatible with Trotec's rotary unit... Allowing you to mark cylindrical parts; like rings, cups, tools, and much more!

Foot Switch: Makes marking multiple jobs quick and easy, just tap the foot switch to trigger the next mark!

Laser Marking - Easy as Printing:

To the operator the DirectMark driver appears as a standard properties dialogue linked to the print function and a printer queue to handle pending jobs.

This was made possible by a team of software developers and laser engineers putting years of experience into Trotec's driver in order to offer features like the material database... Which makes picking the right laser parameters as easy as selecting the material of your choice from a list or the Logo Mode, which automatically vectorizes any graphic before sending it to the laser, making good use of our high speed scan heads.

DirectMark print driver is standard on the ProMarker and available as an option on all SpeedMarker FL Marking Systems.

What are your thoughts? How will (or have) these features help on your production line? What would you like to see on our next release? Looking to keep up-to-date with Trotec? Check out more articles, trade show information, and more under "News" on our website!

Thursday, December 15, 2011

Tips & Tricks: Reverse Engraving

Trotec's unique JobControl Software

offers multiple features that provide functionality, productivity,

flexibility, and reliability to the engraving, cutting, and marking

process!

Trotec's unique JobControl Software

offers multiple features that provide functionality, productivity,

flexibility, and reliability to the engraving, cutting, and marking

process!Today, we are going to highlight reverse engraving.

Generally while processing, the laser starts at the top left corner and ends at the bottom of the engraving job. For some applications and materials, however, it can be helpful to start from the bottom.

Dust and fumes are removed via the rear of the engraving cabinet. This means that the removed material is drawn over the engraved area. Using the reverse engraving means that the dust is drawn over the intact material. Consequently the cleaning process is easier. Reverse engraving is mainly used for engraving of laminates (plastics) and wood

Check this video to find out how this great feature works.

Thursday, November 10, 2011

Tips & Tricks: Positioning Jobs Multiple Times in JobControl

Trotec's unique JobControl Software

offers multiple features that provide functionality, productivity,

flexibility, and reliability to the engraving, cutting, and marking

process!

Today, we are going to highlight the different options available to position multiple jobs; including "Position Jobs Multiple", "2 Plats Together", and "Duplicate Job" and how you can use these features as an aid for laser processing!

These feature are especially beneficial when a material needs to be engraved multiple times with the same design.

To see a demonstration of these features, please visit our website to watch our Positioning Jobs Video!

Position Job Multiple:

When selecting a job in the job queue to process, instead of double clicking (sends job to top right of plate) or dragging (allows you to freely position job on plate) right click on the job and select "Position Job Multiple".

When the "Multiple Placement" window opens, indicate how many times you would like the selected job to be duplicated. Once you've selected "OK" JobControl will automatically position the indicted number of jobs on the plate.

Optimized Sheet Utilization - 2 Plates Together:

If you position two sheets of material side by side in your laser, you can effectively process a job multiple times on two pieces of material while facilitating the "position job multiple" feature.

Open "Plate Setup"; located under "Plate" on the top tool bar. When the "Plate Setup" window opens, check "2 Plates Together" at the bottom of the window and select "OK".

Repeat the steps for "Position Jobs Multiple"

Duplicate Job:

If you have two identical jobs to be processed, you can (1) follow the steps above for "position job multiple" or (2) duplicate the job.

If you choose to duplicate the job, first position the job on the plate. Once you have the job positioned on the plate, right click on the job and select "duplicate job". Job control will automatically potion the a carbon copy of job next to the already positioned job.

Job Control Tip:

The standard value for the plate setup in JobControl is equivalent to the maximum engraving area of the laser you are using (i.e. Speedy 300: 28 in x 18 in).

If you want to use the multiple positioning command on a smaller work piece, try adapting the pate set up value in JobControl to reflect the actual area of the work piece.

Today, we are going to highlight the different options available to position multiple jobs; including "Position Jobs Multiple", "2 Plats Together", and "Duplicate Job" and how you can use these features as an aid for laser processing!

These feature are especially beneficial when a material needs to be engraved multiple times with the same design.

To see a demonstration of these features, please visit our website to watch our Positioning Jobs Video!

Position Job Multiple:

When selecting a job in the job queue to process, instead of double clicking (sends job to top right of plate) or dragging (allows you to freely position job on plate) right click on the job and select "Position Job Multiple".

When the "Multiple Placement" window opens, indicate how many times you would like the selected job to be duplicated. Once you've selected "OK" JobControl will automatically position the indicted number of jobs on the plate.

Optimized Sheet Utilization - 2 Plates Together:

If you position two sheets of material side by side in your laser, you can effectively process a job multiple times on two pieces of material while facilitating the "position job multiple" feature.

Open "Plate Setup"; located under "Plate" on the top tool bar. When the "Plate Setup" window opens, check "2 Plates Together" at the bottom of the window and select "OK".

Repeat the steps for "Position Jobs Multiple"

Duplicate Job:

If you have two identical jobs to be processed, you can (1) follow the steps above for "position job multiple" or (2) duplicate the job.

If you choose to duplicate the job, first position the job on the plate. Once you have the job positioned on the plate, right click on the job and select "duplicate job". Job control will automatically potion the a carbon copy of job next to the already positioned job.

Job Control Tip:

The standard value for the plate setup in JobControl is equivalent to the maximum engraving area of the laser you are using (i.e. Speedy 300: 28 in x 18 in).

If you want to use the multiple positioning command on a smaller work piece, try adapting the pate set up value in JobControl to reflect the actual area of the work piece.

Over to you: Have you tried using any of the JobControl positioning features?

How have they made processing materials easier? What other JobControl features

do you use on a daily basis? What

features would you like to see on our next version of JobControl? Leave your comment in the box below.

Tuesday, October 4, 2011

Tips & Tricks: Using Markers in JobControl

Our unique JobControl Software offers multiple features that provide functionality, productivity, flexibility, and reliability to the engraving, cutting, and marking process!

Today, we are going to highlight the "Markers" and how you can use them as an aid for laser processing!

This feature is especially beneficial when identical items need to be engraved with different designs, as it guarantees the engraving position is precisely defined in advance with each application.

Markers can be added in various ways:

Over to you: How do you use the JobControl "Markers"? What other JobControl features make the engraving, cutting, and marking process easier for you? What features would you like to see on our next version of JobControl? Leave your comment in the box below.

Today, we are going to highlight the "Markers" and how you can use them as an aid for laser processing!

This feature is especially beneficial when identical items need to be engraved with different designs, as it guarantees the engraving position is precisely defined in advance with each application.

Markers can be added in various ways:

- You may define an exact position of the marker (as shown in the video) by inserting the proper coordinates of where you're positioning the material. When the crosshairs appear, the job can be placed in the center of or either corner of the crossharis. Watch the Video of how it works!

- Add the marker to a job that is already positioned on the plate, (Marker to the Job).

- Add the marker to the equivalent position of where the laser head is currently located, (Marker to the Laser).

Over to you: How do you use the JobControl "Markers"? What other JobControl features make the engraving, cutting, and marking process easier for you? What features would you like to see on our next version of JobControl? Leave your comment in the box below.

Thursday, September 1, 2011

JobControl Outline Function

Positioning engraving, cutting, and marking jobs correctly is critical in guaranteeing perfect results. Especially when engraving intricate layouts on expensive or irregular shape materials.

Luckily, Trotec's JobControl's " Job Outline Function" supports both experienced laser and novice users by allowing you to check the correct position prior to starting the engraving job. This feature ensures the job is positioned correctly every time, which prevents faulty engraving and saves you both time and money!

How it works:

- Send the job from your graphics software to the JobControl software.

- Position the material in the laser.

- Position the job on the JobControl plate.

- Select Edit, Outline job(s).

- Watch as the lens carriage begins outlining the shape of the selected job(s). With the laser switched off, the red dot pointer will indicate the outline area of engraving, cutting, and/or marking job.

- The red dot pointer travels along the effective outline, not along the biggest rectangle.

- The laser will continue to outline the job until this action is cancelled. This will give you the opportunity to either move the job to another position on the plate or move the object to be engraved.

- Once you have everything positioned correctly, cancel the job outline function and start engraving.

Subscribe to:

Posts (Atom)