Every seal press consists of two die plates - the positive

(female) and the negative (male).

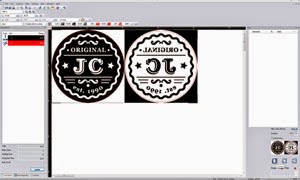

For the positive die plate (displayed as black text/graphics on a white background

in the graphics program) the black elements are engraved into the Delrin

material.

For the negative die plate on the other hand (displayed as

white text/graphics on a black background in the graphics program) the entire

black surface is ablated by the laser.

Consequently, the created text or graphic appears raised on

the die plate. The two die plates need to fit perfectly in each other to

achieve perfect relief print quality. That's why the text/graphic elements must

be produced slightly enlarged on the positive (female) plate. There is no need

to adapt the size of the female plate manually. JobControl X (from version 10.3

on-wards) automatically creates the positive (female) and the negative (male)

die plate with only one click by choosing the process type "Seal" in

the Trotec print driver.

Creating the Graphics

In this example, the graphics are created in CorelDRAW.

However, any other graphics program, such as Adobe Illustrator, Freehand, etc.,

may also be used. Please note that you don't have to draw the outer cutting

line and the positioning nose (triangle recess), JobControl X will do this for

you, allowing you to focus on the elements inside the cutting line - your

layout. JobControl X also automatically enlarges the elements according to the

selected paper thickness for the positive (female) die plate. In the

JobControl X software, we provide predefined seal templates according to

current seal sizes available on the market.

Send Graphics to the Trotec Laser Machine

- Send your graphic design to the laser by using the Trotec

print driver.

- Choose the size of your Seal

- Choose your material; make sure to activate engraving and

cutting process

- Select the process mode "Seal" and choose the

correct paper quality

- Start the laser engraving machine by clicking on the button JC

Produce Your Die Plates with the Trotec Laser Machine

- Your seal job now appears in your job queue; double click to

position the job on the plate at 0/0.

- Job preview is available of the negative (male) and positive

(female) die plate, notice that JobControl automatically created the positive

plate, the cut line, and the positioning nose.

- Now connect to your laser machine and start the laser process.

Machining and Assembly

After the laser processing, you just need to clean the die

plates, pate them into the seal press and then you can already emboss the

paper.

Simply wash the finished Delrin die plates with water and a

little soap or dish liquid and wipe off any still adhering dust with a brush

(clean using compressed air if necessary).

The die plates can be quickly pasted into the seal press

using the supplied doubled-sided adhesive circles. The recessed die plate is

pasted onto the top and the die plate with the raised text is pasted onto the

bottom (at the holes punched into the seal press itself).

- First fix the thicker of the two supplied double-sided

adhesive circles onto the back of the recessed die plate (female) → then paste

this die plate, with the "nose" pointing to the front, on-to the top

part of the seal press

- Now paste the thinner adhesive circle onto the back of the

die plate with the raised text (male) → pull off the carrier material on the

back → now fix the die plate with the raised text into the recess of the

already installed die plate, so that the two die plates snap together

- Tip: the two noses on the die plates should be perfectly aligned on top of each other → now press down on the seal press, whereby the second plate is fixed into the press → you can now place a piece of paper into the fully assembled seal press → press down → result: relief embossed paper

No comments:

Post a Comment